Snowboard Press

Design and build a pneumatic snowboard press

A custom pneumatic snowboard press combining innovative single-bladder technology with modular design to deliver professional-grade composite forming.

Abstract

This project details the design, construction, and implementation of a pneumatic snowboard press system optimized, modularity, and pressing efficiency. The press incorporates a bolt-together frame design rated for 30 tons (operating at 6 tons), an innovative single-bladder pneumatic system, and Arduino-based temperature control. The resulting system produces high-quality thermocompression composites while maintaining simplified mold changeover procedures and reduced operational complexity compared to traditional multi-bladder designs.

1. Introduction

1.1 Project Overview

The pneumatic press represents the most critical piece of equipment in snowboard manufacturing, both in physical scale and functional importance. This project aimed to develop a press system that balances structural integrity, operational safety, production efficiency, and high-quality thermo-composites.

1.2 Design Objectives

Engineer a structurally sound press capable of handling continuous high-stress operations

Ensure modularity for multiple board sizes and future upgrades

Simplify the pressing process compared to industry-standard designs

Achieve reliable production of high-quality composite boards

Maintain cost-effectiveness throughout design and construction

2. System Design

2.1 Press Frame

A bolt-together design was selected for its simplicity. This bolt-together approach facilitates assembly, maintenance, and potential future modifications.

2.1.1 Structural Design Philosophy

Design Load Capacity: 30 tons

Operational Load: 6 tons

Total System Weight: Approximately 1,500 lbs (including molds and hardware)

Safety Factor: 5:1 (designed capacity vs. operational load)

The substantial safety margin ensures long-term structural integrity and allows for potential process expansion.

2.1.2 Technical Specifications

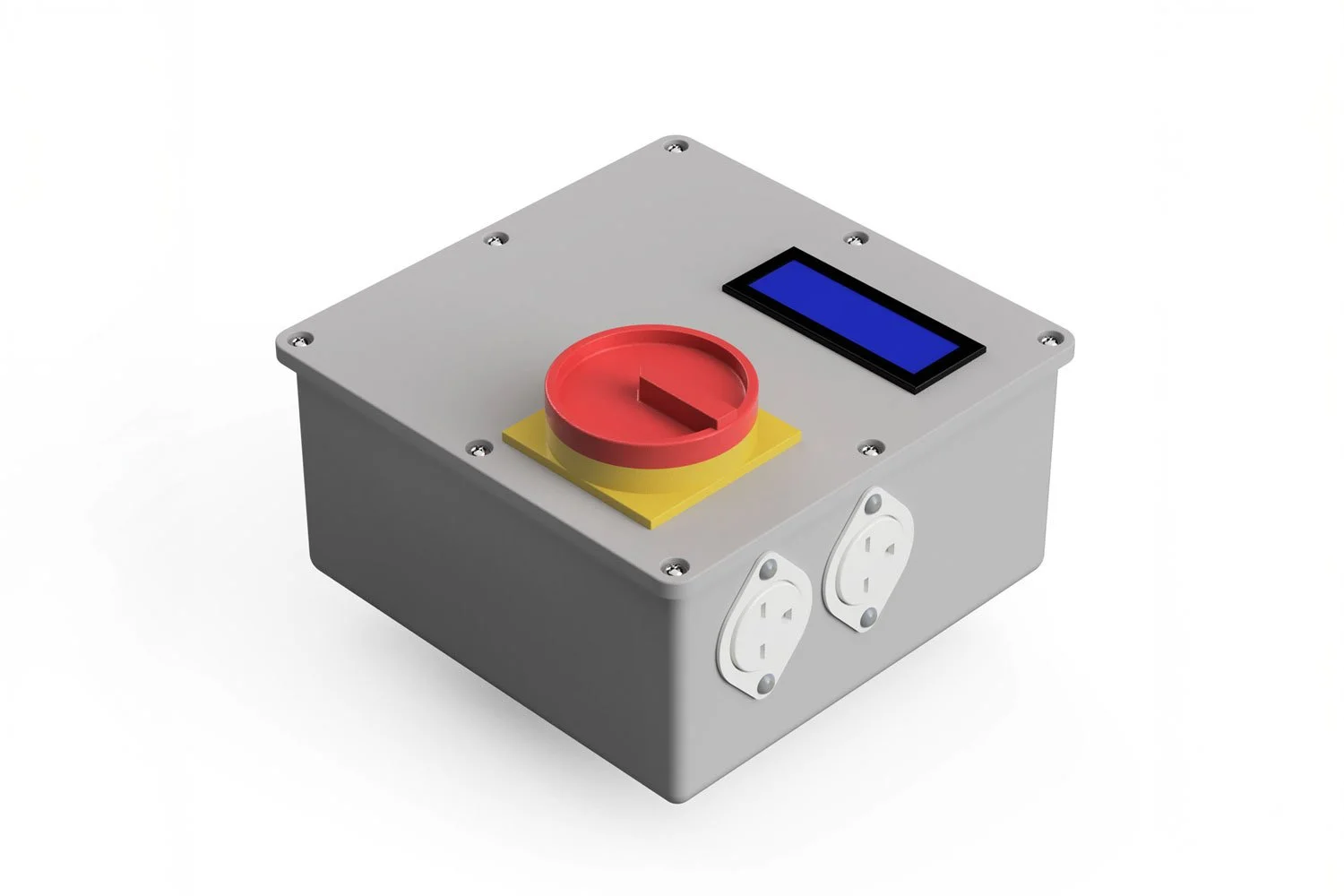

2.2 Control Systems

2.2.1 Pneumatic Control

2.2.2 Thermal Management

Temperature regulation is achieved through an Arduino-based controller managing two 25A SSRs into two silicone heat blankets operating at 240V. Two type K thermocouples were used, one for the top heat blanket and one for the bottom heat blanket. The Arduino platform was selected for its:

Reliable temperature regulation capabilities

Ease of programming and calibration

Upgrade pathway for future automation implementation

Cost-effectiveness and component availability

Alternative temperature controller options could be a 1/16 DIN temp controller or a Raspberry Pi. Use ChatGPT or your favorite AI to write the code and test until you have a system that works for your purpose.

No special programming for ramp up or ramp down was needed to make sound composites. Just turning the system on or off ramped the temperature perfectly for this application. Cure time started when the blankets reached full temp and ran the duration required by the resin. Cool down took some experimentation to not waste time. All times were controlled with a simple timer.

3. Sub-Assembly Development

3.1 Mold System

Molds define the geometric profile of a finished snowboard. Each board profile needs it’s own mold so easy press changeover is a nice goal if you plan on pressing multiple board sizes or profiles.

3.1.1 Design Requirements

Medium-Density Fiberboard (MDF) was selected as the mold material based on:

Adequate compressive strength for pressing operations

Superior cost-effectiveness compared to metal alternatives

Ease of machining and modification

3.1.2 Material Selection

Molds were designed with minimal material usage to achieve three primary objectives:

Reduced changeover time between production runs

Lower per-unit material costs

Less storage space

A CNC-machined, vertically laminated particle board block serves as the base platform, providing a flat, stable surface to support the bottom mold during pressing operations.

3.1.3 Mold Construction

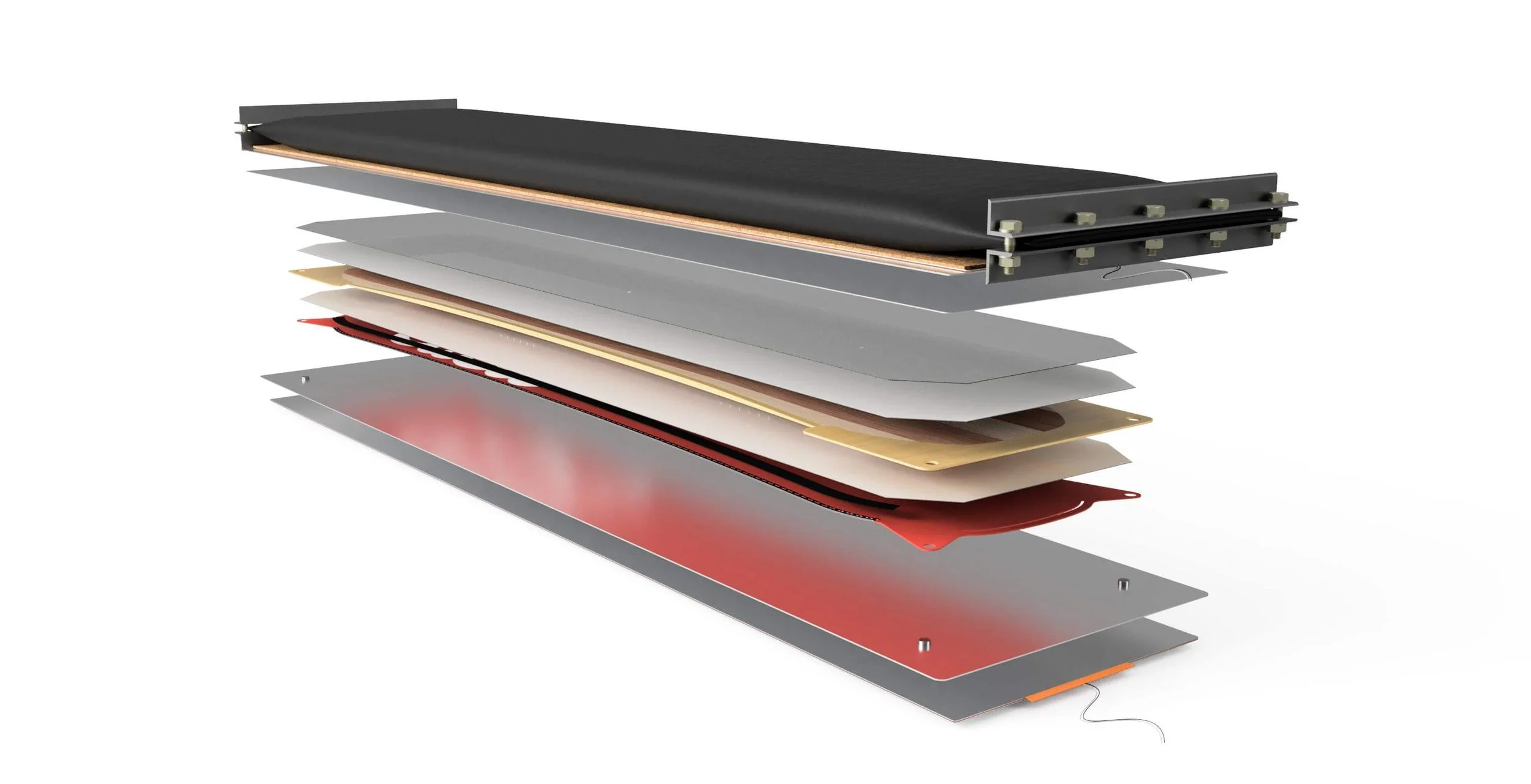

3.2 Bladder System

Sourcing appropriate bladder components required significant research and procurement effort, ultimately proving essential to the system's performance advantages.

3.2.1 Development Process

3.2.2 Innovation: Single-Bladder Design

This project diverged from the industry-standard multi-bladder configuration by implementing a simplified single-bladder design. This innovation was enabled by:

Precise engineering of the gap distance between top and bottom molds

Elimination of complex "cat track" pressure distribution system

The single-bladder approach delivered multiple operational advantages:

Reduced Operating Bladder Pressure: Lower pneumatic pressures required for equivalent compression

Improved Composite Quality: More uniform pressure distribution produces superior laminates

Simplified Changeover: Fewer components to remove and reinstall between mold changes

Reduced System Complexity: Fewer potential failure points and simpler maintenance

3.2.3 Performance Benefits

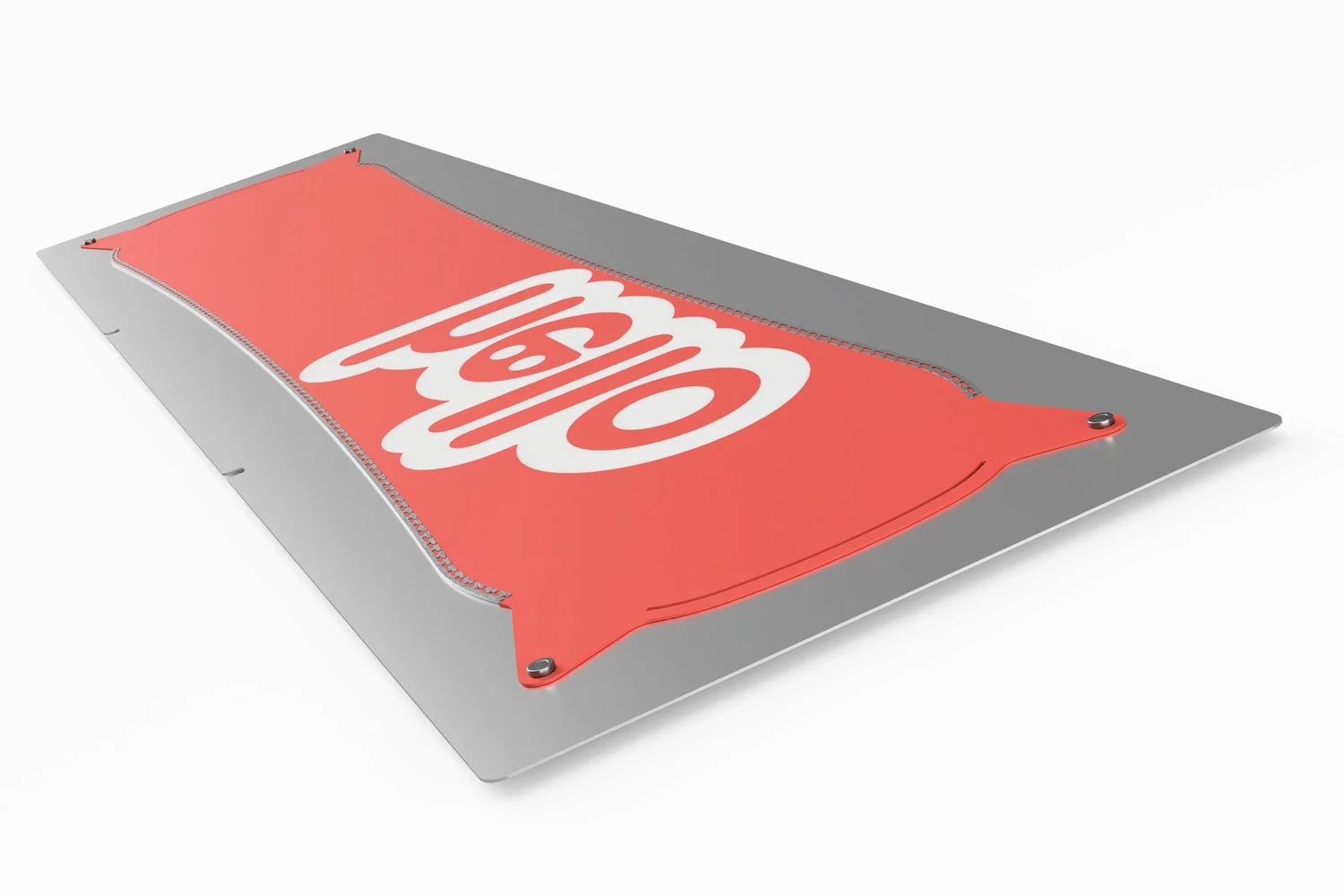

3.3 Cassette Assembly

3.3.1 Functional Requirements

The cassette serves as the lamination platform, maintaining precise component positioning throughout the compression cycle as pressure develops.

3.3.2 Design Solution

A streamlined design utilizing an aluminum sheet with positioning pins provides:

Component Registration: Pins ensure accurate placement of all lamination layers

Multi-Size Compatibility: Single cassette accommodates various board dimensions

Ease of Cleaning: Smooth aluminum surface facilitates rapid post-press cleanup

Cost Efficiency: Simple construction minimizes material and fabrication costs

The cassette was referenced to the mold in the press using to post mounted to the particle board block supporting the lower mold. You can see two notches on the back edge of the cassette. These notches would match with the posts when the loaded cassette was slid into the press cavity. Once inserted pressure was added and they entire cassette stack was held firmly in place and reference properly to the mold.

4. Results and Performance Analysis

4.1 System Integration

The integrated press system successfully achieved all primary design objectives, demonstrating:

Structural reliability under operational loads

Consistent production of high-quality thermocompression composites

Efficient workflow with minimized changeover times

4.1 System Integration

The simplified pressing mechanics, particularly the single-bladder system, consistently produces composites of exceptional quality, meeting or exceeding industry standards for snowboard construction.

4.3 Operational Efficiency

Mold changeover procedures were significantly streamlined compared to traditional multi-bladder designs, directly improving production flexibility and throughput.

5. Discussion

5.1 Design Success Factors

The project's success can be attributed to several key design decisions:

Safety-First Engineering: Over-designed structural capacity ensures long-term reliability

Strategic Simplification: Single-bladder innovation reduced complexity without compromising quality

Modular Architecture: Bolt-together construction and standardized cassette enable future expansion

Material Optimization: Appropriate material selection balanced performance and cost

5.2 Economic Viability

The press demonstrates strong economic performance through:

Minimal capital investment compared to commercial alternatives

Reduced operational costs via simplified design

Lower maintenance requirements due to fewer complex subsystems

5.3 Future Upgrade Potential

The Arduino-based control system and modular mechanical design provide clear pathways for:

Process automation implementation

Integration of data logging and quality monitoring

Adaptation to new board geometries and construction techniques

6. Conclusion

The pneumatic snowboard press project successfully delivered a cost-effective, reliable, and modular manufacturing solution. By challenging industry-standard approaches, particularly through the innovative single-bladder design, the system achieves superior composite quality while maintaining operational simplicity.

The press's modular architecture and upgradeable control systems position it well for adaptation to evolving production requirements and future board designs. The straightforward mechanics of this pressing system consistently produce high-quality thermocompression composites, validating the design approach and demonstrating that simplified engineering can deliver professional-grade manufacturing capability.

7. Technical Summary

| Parameter | Specification | Manufacturer |

|---|---|---|

| Design Load Capacity | 30 tons | — |

| Operational Load | 6 tons | — |

| Total System Weight | ~1,500 lbs | — |

| Main I-Beams | 4× W10x33, 96" long | — |

| Cross I-Beams | 2× W12x40, 16" long | — |

| Control Voltage | 240V | — |

| Heat Blankets | 2× MEI silicone | michaelsenterprises.com |

| Control System | Arduino-based | — |

| Pneumatic Control | Manual 4-way valve | — |

| Mold Material | MDF | — |

| Cassette Material | Aluminum sheet | — |

| Bladder Configuration | Single-bladder design | — |

8. References and Resources

Acknowledgments

Happy Monkey Snowboards

happymonkeysnowboards.com served as a significant source of inspiration and information during the development of this press system. The website provides extensive, detailed information for anyone interested in building snowboard manufacturing equipment, covering design principles, construction techniques, and practical considerations for DIY press building. Their openly shared knowledge base proved invaluable to this project's success and is highly recommended for anyone pursuing similar snowboard press construction projects.

skibuilders.com

Although, I believe at the time of this post, skibuilders.com is not functioning. This was a great resource of home brew ski and snowboard knowledge and experimentation. Hopefully in the future this great resource will return.