For many years, snowboards suffered from poor design. They were basically skis that were widend. Not all, but many of them were produced using this idea. Skis and snowboards work fundamentally different and should be designed differently. The scope of this project was to do just that. To create a great all-mountain snowboard that was light-weight and manufactured as environmentally responsible as possible. Many hours of R&D resulted in the following design.

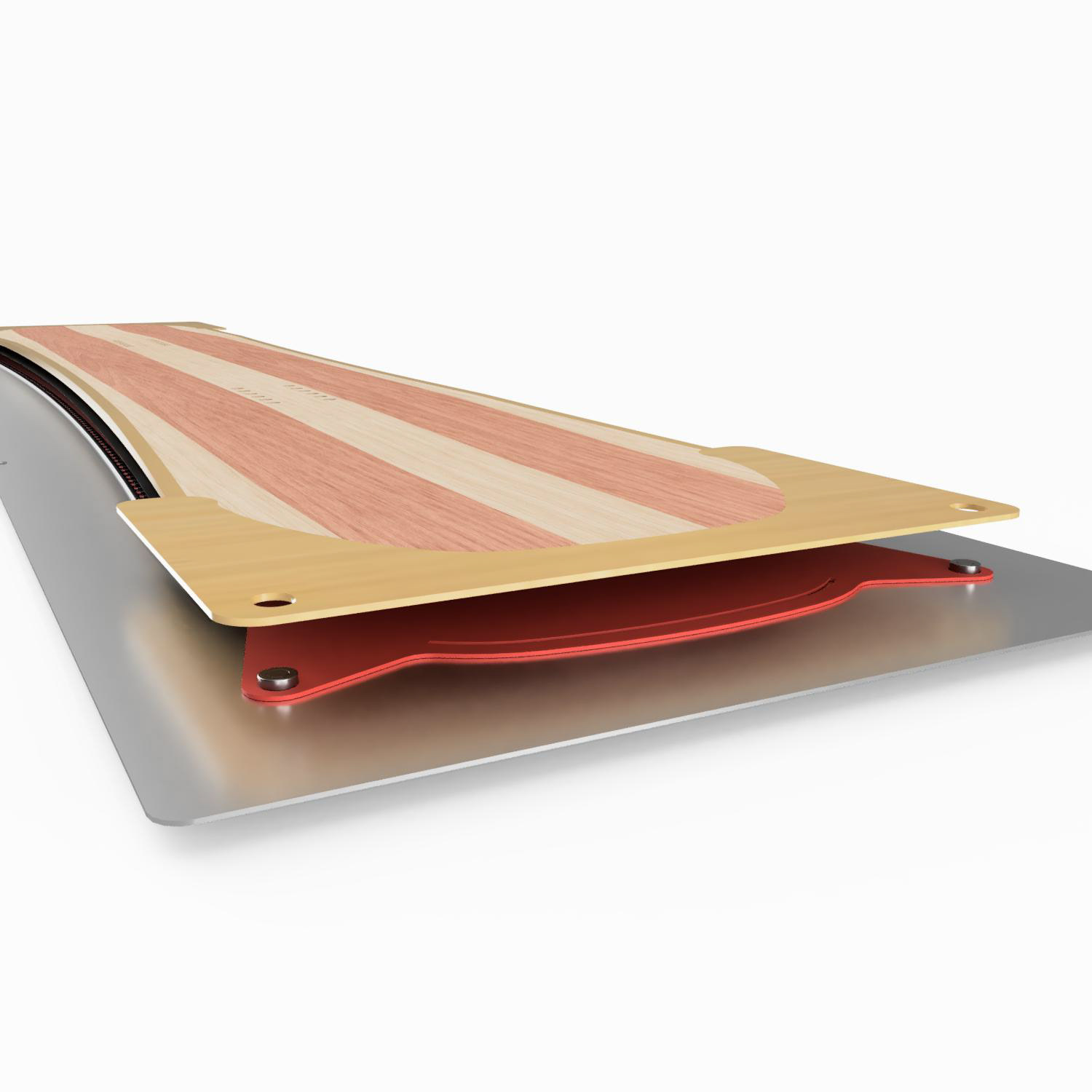

A number of ideas for the geometry, construction and materials were tried in the prototype phase. Poplar and lightweight Paulownia were chosen for the core along with Crown Plastics base and topsheet material. One area where the boards differed from the industry standard was the sidewall material, FSC certified bamboo was chosen instead of plastics. Bamboo is very strong and tough in this application with added bonding strength over similarly used plastics. Vectroply triaxial fiberglass was used with Entropy Resins to keep with the environmentally friendly goal. The geometry of the board was perfected along with the pressing and lay-up methods during the entire R&D phase.