All Mountain Snowboard

The Project: Build a fuckin’ snowboard

Technical documentation for building a custom all-mountain snowboard using sustainable materials, innovative construction methods, and snowboard-specific engineering principles. Covers material selection, CNC fabrication, graphics application, and the complete R&D process.

Abstract

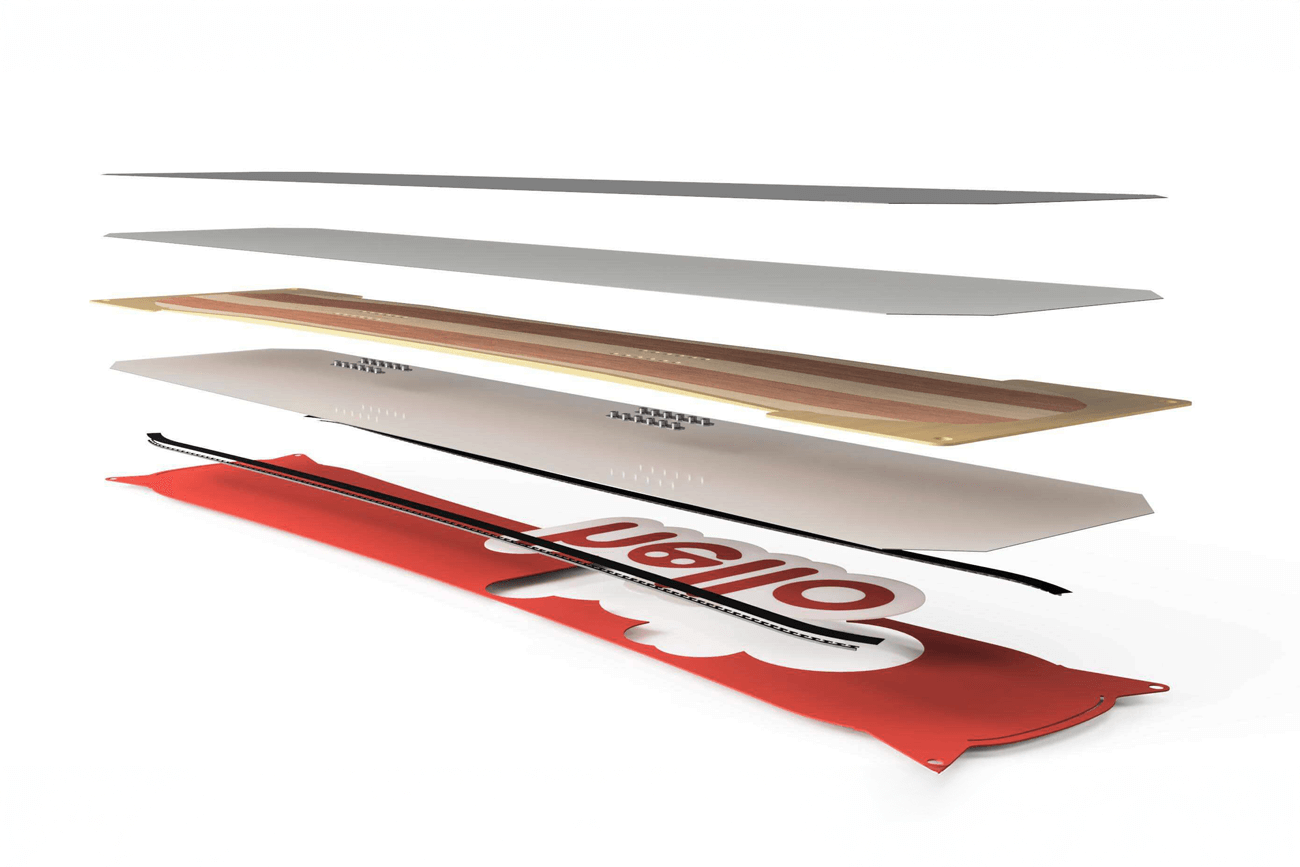

This project focuses on developing a high-performance all-mountain snowboard through thoughtful design optimization, advanced material selection, and precision manufacturing techniques. Through extensive research and development, a refined construction approach was implemented utilizing high-performance materials including lightweight Paulownia wood cores, bamboo sidewalls, and advanced composite systems. The resulting design demonstrates how careful attention to geometry, material properties, and construction methods can produce exceptional snowboard performance.

1. Introduction

1.1 Problem Statement

For many years, snowboard design suffered from a fundamental misconception in the industry. Numerous manufacturers approached snowboard construction by simply widening ski designs, applying ski-based engineering principles to a fundamentally different application. While not universal, this practice was widespread throughout the industry.

1.2 Fundamental Design Philosophy

Skis and snowboards operate under fundamentally different biomechanical principles and force distributions. Effective snowboard design requires recognition of these differences and application of snowboard-specific engineering approaches rather than adapted ski methodologies.

1.3 Project Objectives

The scope of this project encompassed:

Design and engineer a high-performance all-mountain snowboard

Minimize board weight without compromising structural integrity

Select premium materials optimized for snowboard construction

Develop construction methods optimized specifically for snowboard performance characteristics

2. Research and Development Process

2.1 R&D Methodology

Extensive research and development was conducted across multiple design iterations, exploring various approaches to:

Board geometry and flex patterns

Core construction materials and layup configurations

Composite reinforcement strategies

Manufacturing process optimization

2.2 Prototype Phase

The prototype phase served as the primary vehicle for testing and refining design concepts. Multiple iterations allowed for systematic evaluation of:

Geometric parameters and their performance implications

Material combinations and their structural characteristics

Manufacturing techniques and their consistency

On-snow performance across varied conditions

Areas that were constantly under experimentation were:

Tip and Tail shapes

Core profiles

Core materials

Mold profiles

Sidewall materials

Topsheet and base materials

2.3 The First Board

The first board popped out of the press and exceeded expectations. The bamboo core was great for soaking up bumps and ruts. It also carved groomers like it was on rails. It was easy to layup too and that was good for production, but overall the board was too heavy, you really noticed it hanging on your foot while stuck on the lift. It also lacked any kind of pop in its flex in it’s buttery flex pattern.

3. Material Selection and Engineering

3.1 Core Construction

3.1.1 Material Selection Criteria

Core material selection prioritized three key factors:

Structural Performance: Adequate strength-to-weight ratio for all-mountain use

Weight Optimization: Minimal density without compromising integrity

Workability: Ease of machining and bonding characteristics

3.1.2 Selected Materials

A hybrid core construction was developed utilizing:

Poplar Wood

Provides structural strength and traditional flex characteristics

Established performance record in snowboard construction

Excellent bonding properties

Paulownia Wood

Exceptional strength-to-weight ratio

Significantly lighter than traditional core materials

Superior stiffness-to-weight characteristics

3.2.1 Crown Plastics System

Crown Plastics was selected for both base and topsheet applications based on:

Proven durability in snowboard applications

Consistent manufacturing properties

Industry-standard performance characteristics

Durasurf 2001 or 4001 for base material

Durasurf PE Blend 0.020 topsheet

3.3 Sidewall Innovation

3.3.1 Departure from Industry Standard

The design deliberately diverged from the industry-standard practice of plastic sidewalls, implementing an innovative alternative material.

3.3.2 FSC-Certified Bamboo Sidewalls

Bamboo was selected as the sidewall material, representing a significant departure from conventional construction:

Superior strength characteristics in sidewall applications

Exceptional toughness and impact resistance

Enhanced bonding strength compared to plastic alternatives

Improved mechanical adhesion properties

Natural aesthetic that complements wood core visibility

3.4 Composite Reinforcement System

3.4.1 Fiberglass Selection

Vectroply E TLX 1900 Triaxial Fiberglass was specified for structural reinforcement:

Triaxial weave provides multidirectional strength

Optimized fiber orientation for snowboard load patterns

Superior torsional rigidity compared to biaxial alternatives

3.2 Base and Topsheet Materials

3.4.2 Resin System

Entropy Resins CPM bio-based epoxy system was selected to maintain environmental objectives:

Partially bio-based resin formulation

Reduced VOC emissions during manufacturing

Excellent wet-out characteristics for fiberglass lamination

Superior bond strength across all materials

Consistent cure properties for reliable manufacturing

4. Design Optimization

4.1 Geometric Development

Board geometry underwent iterative refinement throughout the R&D phase, addressing:

Sidecut radius and effective edge optimization

Flex pattern distribution and progression

Nose and tail shape for varied snow conditions

Stance positioning and reference points

4.1 Pressing Methods

Manufacturing processes were developed and refined to ensure:

Consistent laminate compression across the board profile

Optimal resin distribution and fiber wet-out

Repeatable geometric accuracy

Minimal void formation in composite structures

4.3 Lay-up Techniques

Lamination procedures were systematically optimized for:

Proper fiber orientation and layer sequencing

Efficient production workflow

Quality consistency across production runs

Minimization of material waste

4.4 CNC Machining and Fabrication

A custom CNC router was constructed utilizing components from AvidCNC to provide precision machining capabilities essential to consistent board production.

System Applications:

Core cutting and profiling

Precision shaping of core geometries

Consistent dimensional accuracy across production

Efficient material utilization

Component Source: avidcnc.com

4.4.1 Custom CNC Router System

Base material cutting was accomplished using the custom CNC router equipped with a Donek drag knife system.

Donek Drag Knife Advantages:

Clean, precise cuts in base material

Eliminates need for manual cutting and trimming

Repeatable accuracy for consistent board profiles

Reduced material waste through optimized toolpathing

Component Source: donek.com

4.4.2 Base Material Cutting

The CNC machining capability proved essential to the project's success by:

Ensuring geometric consistency across all board components

Reducing manual labor and potential human error

Enabling rapid prototyping during R&D phase

Supporting efficient transition from prototype to production

The investment in custom CNC infrastructure provided manufacturing capabilities typically reserved for larger production facilities, demonstrating that precision board building is achievable at smaller scales with appropriate tooling.

4.4.3 Manufacturing Integration

5. Graphics and Topsheet Decoration

5.1 Design Approach

The aesthetic design strategy emphasized the natural beauty of the wood core construction. By utilizing a clear topsheet material, the visual character of the Poplar and Paulownia core remains visible, creating a distinctive organic appearance that celebrates the board's construction rather than concealing it.

5.2 Graphics Application Methods

5.2.1 Selected Method: Epoxy Screen Printing

Epoxy-Based Screen Printing Ink was selected as the primary graphics application method:

Process Characteristics:

Single-color format application

Epoxy ink chemistry compatible with resin system

Direct application to topsheet surface

Minimal visual obstruction of core visibility

Design Philosophy: The single-color approach complements rather than dominates the natural wood aesthetic, allowing the core's visual characteristics to remain the primary design element while adding branded or decorative elements where desired.

5.2.2 Alternative Method: Dye Sublimation

Dye sublimation represents a high-volume production approach offering:

Advantages:

Full-color, photographic-quality graphics

Highly durable image integration

Professional production appearance

Consistent repeatability across production runs

Implementation Barriers:

Significant capital equipment investment required

Complex engineering and process development

Substantial technical expertise necessary

Heat press equipment and specialized transfer systems

Project Decision: While dye sublimation offers aesthetic versatility, the capital requirements and engineering complexity exceeded the project's resource allocation and immediate production needs.

An innovative, cost-effective graphics method adapted from surfboard manufacturing:

Process Overview:

Standard inkjet printing on specialized rice paper

Rice paper positioned in lamination stack beneath topsheet

Integration into composite during pressing cycle

Resin saturation renders rice paper substrate invisible

Method Advantages:

Minimal capital investment (standard inkjet printer)

Full-color graphics capability

Easy customization and design iteration

Proven effectiveness in surfboard applications

Technical Considerations:

Rice paper selection critical for proper transparency

Proper resin saturation essential for substrate invisibility

Positioning accuracy important during layup

Ink compatibility with epoxy resin system

Application Suitability: This method provides an accessible entry point for custom graphics and small-batch production, offering professional results without the capital investment required for dye sublimation systems.

5.2.3 Alternative Method: Rice Paper Inkjet Transfer

5.3 Graphics Method Comparison

| Method | Cost | Complexity | Color Options | Visual Result | Best For |

|---|---|---|---|---|---|

| Epoxy Screen Print | Low | Low | Single color | Clean, minimal | Emphasizing natural core visibility |

| Dye Sublimation | High | High | Full color | Professional, photographic | High-volume production |

| Rice Paper Inkjet | Very Low | Low | Full color | Custom, detailed | Custom builds, small batches |

6. Results and Performance Analysis

6.1 Design Achievement

The R&D process successfully yielded a refined snowboard design incorporating:

Optimized geometry specific to snowboard performance requirements

Lightweight construction without structural compromise

Environmentally responsible material selection throughout

Manufacturing processes capable of consistent production

Flexible graphics options accommodating various aesthetic approaches

6.2 Material Performance

The selected material combination demonstrated:

Excellent strength-to-weight characteristics

Superior bonding performance, particularly with bamboo sidewalls

Reliable structural integrity across varied conditions

Environmental benefits without performance penalties

6.3 Manufacturing Success

Developed pressing and lay-up methods proved:

Repeatable and consistent across production

Capable of maintaining tight geometric tolerances

Efficient in material utilization

Scalable for increased production volume

7. Discussion

7.1 Design Philosophy Validation

The project successfully demonstrated that snowboard-specific design approaches yield superior results compared to adapted ski construction methods. By recognizing the fundamental differences in how these platforms function, the design achieved performance characteristics optimized for snowboarding biomechanics.

7.2 Innovation in Material Application

7.2.1 Bamboo Sidewall Innovation

The use of bamboo as a sidewall material represents a significant innovation delivering superior performance:

Technical Merit: The superior bonding strength and mechanical properties of bamboo validate its use based purely on performance considerations. This material choice delivers genuine structural advantages over conventional plastic sidewalls.

Industry Implications: This successful application challenges the default use of plastic sidewalls and demonstrates that alternative materials can offer superior performance characteristics.

7.3 Material Selection Excellence

The project achieved its material performance objectives through:

Strategic selection of premium materials optimized for snowboard construction

Implementation of advanced composite systems

Use of lightweight core materials without performance sacrifice

Development of manufacturing processes that maximize material properties

Critically, these material choices delivered superior performance characteristics, demonstrating that innovative material selection and thoughtful engineering produce exceptional results.

7.4 Lightweight Construction

The incorporation of Paulownia wood core sections successfully reduced board weight while maintaining structural requirements for all-mountain performance. This weight reduction enhances:

Rider maneuverability and control

Reduced fatigue during extended use

Improved swing weight for aerial maneuvers

Enhanced responsiveness in varied conditions

7.5 Graphics Flexibility

The project successfully identified and evaluated multiple graphics application methods, each serving different production scenarios:

Epoxy Screen Printing proved ideal for the project's aesthetic philosophy, allowing the natural core beauty to remain the dominant visual element while providing branding capability.

Rice Paper Inkjet Transfer emerged as a valuable discovery, offering a low-barrier entry to custom graphics that democratizes access to professional-looking results without significant capital investment. This method's adaptation from surfboard manufacturing demonstrates the value of cross-industry innovation.

Dye Sublimation remains a future consideration for scaled production, with its capital requirements and complexity acknowledged but deferred pending production volume justification.

This multi-method approach provides flexibility across different production scales and customer requirements, from one-off custom builds to potential production runs.

8. Conclusion

This project successfully developed a high-performance all-mountain snowboard that challenges conventional industry approaches on multiple fronts. By rejecting the historical practice of adapting ski design principles to snowboard construction, the design achieves performance characteristics specifically optimized for snowboarding biomechanics.

The extensive R&D process yielded refined solutions across all design aspects: geometry, material selection, and manufacturing processes. The resulting snowboard demonstrates that environmental responsibility and lightweight construction can be achieved without compromising performance when approached through thoughtful engineering and material science.

The innovative use of FSC-certified bamboo sidewalls, combined with Paulownia core sections and bio-based resin systems, establishes a template for sustainable snowboard construction that delivers genuine performance advantages. The developed manufacturing processes ensure these design innovations can be consistently reproduced, supporting both custom builds and potential scaled production.

9. Technical Summary

| Component | Material/Specification | Key Characteristics | Manufacturer |

|---|---|---|---|

| Core Material (Primary) | Poplar | Structural strength, traditional flex | — |

| Core Material (Secondary) | Paulownia | Lightweight, exceptional strength-to-weight ratio | — |

| Sidewalls | Bamboo | Superior bonding, high strength, natural aesthetic | — |

| Steel Edges | Steel | Precision edge hold and durability | waelzholz.com |

| Base Material | Crown Plastics | Industry-standard durability | crownplastics.com |

| Topsheet Material | Crown Plastics | Proven performance characteristics | crownplastics.com |

| Reinforcement | Vectorply E TLX 1900 Triaxial Fiberglass | Multidirectional strength, optimized torsion | vectorply.com |

| Resin System | Entropy Resins | High-performance epoxy, superior bond strength | entropyresins.com |

| Design Category | All-Mountain | Versatile performance across conditions | — |

| Design Philosophy | Iterative design refinement | Optimized through extensive R&D and testing | — |

| CNC Router System | Custom-built with AvidCNC components | Core cutting, shaping, precision fabrication | avidcnc.com |

| Base Cutting Tool | Donek Drag Knife | Precise base material cutting on CNC | donek.com |

| Graphics Method (Selected) | Epoxy Screen Printing Ink | Single-color, preserves core visibility | — |

| Graphics Method (Alternative 1) | Dye Sublimation | Full-color, high-volume capability | — |

| Graphics Method (Alternative 2) | Rice Paper Inkjet Transfer | Full-color, low-cost custom graphics | — |